tile cutter manual

Tile cutters are essential tools for cutting tiles efficiently and accurately. Available in manual and electric models, they enable precise scoring and snapping for various tile materials.

These tools are ideal for DIY projects and professional use, offering versatility and control. They simplify tile installation, ensuring clean cuts and professional-looking results every time.

1.1 What is a Tile Cutter?

A tile cutter is a specialized tool designed to cut tiles accurately and efficiently. It is available in manual and electric versions, with the manual type being portable and cost-effective.

Manual tile cutters work by scoring the tile surface and then snapping it along the scored line. They are ideal for small to medium projects, offering precision and ease of use.

These tools are essential for both DIY enthusiasts and professionals, ensuring clean and professional-looking cuts for various tile materials, including ceramic, porcelain, and natural stone.

1.2 Importance of Using a Tile Cutter

Using a tile cutter is crucial for achieving precise and clean cuts, minimizing waste, and ensuring professional-looking results. It helps maintain accuracy and consistency, especially when working with expensive or delicate materials.

A tile cutter also saves time and effort by allowing quick adjustments and repeated cuts. Its versatility makes it an essential tool for both small DIY projects and large-scale renovations, ensuring efficiency and quality in every cut.

Types of Tile Cutters

Tile cutters are available in manual and electric models, each designed for specific needs. Manual cutters are portable and cost-effective, while electric models offer precision and speed.

2.1 Manual Tile Cutters

Manual tile cutters are portable and easy-to-use tools designed for precise scoring and snapping of tiles. They are ideal for small to medium-sized projects, offering simplicity and control.

These cutters feature a sturdy frame, a scoring wheel, and a breaking mechanism. They are cost-effective and require minimal setup, making them perfect for DIY enthusiasts and professionals alike.

Manual cutters are suitable for most tile materials, including ceramic, porcelain, and natural stone, ensuring clean and accurate cuts without the need for electricity or complex equipment.

2.2 Electric Tile Cutters (Wet Saws)

Electric tile cutters, also known as wet saws, are powerful tools designed for precise and efficient cutting of tiles. They feature a diamond-coated blade and a water cooling system.

These cutters are ideal for large projects and thick or hard tiles. They offer high torque and adjustable mitre guides for angled cuts. Models like the Titan Tile Cutter and MTC500 provide advanced features.

Electric cutters are faster than manual ones but require proper setup and water supply to minimize dust and prevent overheating, making them a professional choice for complex tasks.

Choosing the Right Tile Cutter

Selecting the right tile cutter depends on tile size, material, and project scope. Manual cutters are ideal for small tasks, while electric models suit large projects.

Consider the cutter’s capacity, blade quality, and additional features like water recirculation for efficiency and dust reduction, ensuring optimal performance for your specific needs.

3.1 Factors to Consider (Tile Size, Material, etc.)

When selecting a manual tile cutter, consider tile size, material, and thickness. Ensure the cutter’s capacity exceeds the tile’s dimensions by at least 1 inch for precise cuts.

Different materials, such as ceramic, porcelain, or natural stone, may require specific blades or cutting techniques. The cutter’s durability and ease of use are also crucial factors.

Additionally, assess the project’s scope and frequency of use to determine if a manual or electric cutter is more appropriate for your needs.

3.2 How to Select the Appropriate Cutter for Your Project

To select the right manual tile cutter, measure your tiles and choose a cutter with a capacity at least 1 inch larger than the tile’s dimensions.

Consider the tile material—ceramic, porcelain, or natural stone—and ensure the cutter’s blade is suitable for the hardness of the material.

Evaluate the project’s scope: small DIY tasks may require a basic cutter, while larger projects demand more robust tools.

Check for features like adjustable fences for straight cuts or miter guides for angled cuts to enhance precision and versatility.

Safety Precautions

Keep your work area clean and well-lit to prevent accidents. Avoid clutter and ensure good visibility while operating the tile cutter.

Wear protective gloves and goggles to safeguard against debris. Never operate power tools in explosive environments or near flammable materials.

4.1 Work Area Safety Tips

Ensure your workspace is clean, well-lit, and free from clutter to minimize accident risks. Keep explosive materials and flammable substances away from the area.

Use protective gloves and goggles to prevent injury from debris. Maintain good ventilation, especially when cutting materials that produce dust or fumes.

Secure loose clothing or jewelry that could get caught in the tile cutter. Always operate the tool on a stable, flat surface to maintain control and balance.

4.2 Personal Protective Equipment (PPE)

Wearing appropriate PPE is crucial when using a manual tile cutter. Always wear safety goggles or glasses to protect your eyes from flying debris.

Use durable gloves to maintain a firm grip and prevent cuts from sharp tile edges. A dust mask is recommended to avoid inhaling particles during cutting.

Ensure loose clothing or jewelry is secured to avoid accidental entanglement with the tool. Proper PPE ensures a safer and more controlled cutting experience.

Step-by-Step Guide to Using a Manual Tile Cutter

Measure and mark the tile, align it with the cutter, score firmly, and snap cleanly for precise cuts. Always follow safety guidelines for optimal results.

5.1 Preparing the Tile and Cutter

Start by ensuring the tile is clean and dry, free from dust or debris. Inspect the tile for any cracks or damage before cutting. Next, assemble the manual tile cutter according to the manufacturer’s instructions, ensuring all parts are securely in place. Place the cutter on a stable, flat surface and align the tile under the scoring wheel. Always wear safety goggles and gloves for protection. Double-check that the blade is sharp and properly positioned to avoid uneven cuts. Proper preparation ensures accurate and safe cutting results.

5.2 Measuring and Marking the Tile

Measure the tile carefully using a tape measure or ruler, marking the desired cut line with a pencil. Use a square to ensure accurate alignment. Place the tile on the cutter bed, aligning the marked line with the scoring wheel. Double-check the measurements to avoid errors. For straight cuts, use a straightedge as a guide. For curved cuts, mark the outline with a compass or stencil. Ensure all markings are clear and visible before proceeding. Proper measurement and marking are crucial for precise cutting results with a manual tile cutter.

5.3 Scoring the Tile

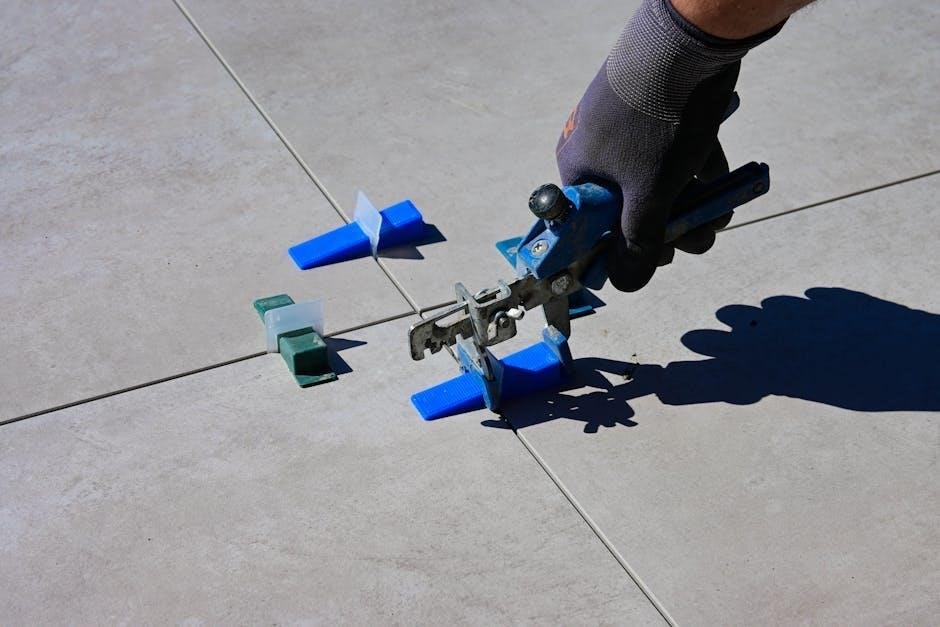

Scoring the tile is a critical step in the cutting process. Place the tile firmly on the cutter bed, aligning the marked line with the scoring wheel. Hold the handle steady and apply gentle, consistent pressure, moving the wheel from one end of the tile to the other in a smooth, continuous motion. Ensure the scoring wheel is properly positioned to avoid deviations. The goal is to create a clear, visible line that guides the snapping process. Proper scoring ensures a clean break and minimizes the risk of uneven edges or shattered tile.

5.4 Snapping the Tile

After scoring, place the tile on the cutter’s breaking edge. Apply gentle, consistent pressure downward on the handle to snap the tile along the scored line. For smaller tiles, breaking pliers can be used to grip and snap the tile precisely. Ensure the tile is aligned correctly before applying pressure to avoid uneven breaks. If the tile does not snap cleanly, check the score line for depth and accuracy. Always wear safety gloves to protect your hands during this step. Proper snapping technique ensures clean, professional results.

Tips for Accurate Cutting

Align the tile snugly against the fence and use a straightedge for guidance. Apply consistent pressure while scoring to ensure clean, precise cuts. Always use a sharp scoring wheel for accurate lines.

6.1 Ensuring Straight Cuts

To ensure straight cuts with a manual tile cutter, align the tile snugly against the fence and use the scoring wheel to create a clear, visible line. Apply consistent pressure while scoring, as uneven pressure can lead to crooked cuts. Use a straightedge or guide to help maintain alignment, especially for longer tiles. Always double-check the marked line before scoring to ensure accuracy. For precise results, keep the cutter’s blade or wheel sharp, as a dull edge can cause the tile to break unevenly.

6.2 Cutting Curves and Holes

Cutting curves and holes in tiles requires precision and the right techniques. For manual tile cutters, this can be challenging, as they are primarily designed for straight cuts. However, using a combination of scoring and snapping, you can achieve intricate shapes by making multiple small, precise cuts around the desired curve or hole. For complex designs, consider using an angle grinder with a diamond blade or a specialized tile nipper for smoother, more accurate results.

Always use a guide or stencil to help maintain control and ensure the cuts align with your design. Safety is crucial, so wear protective gear and work slowly to avoid mistakes.

Common Mistakes to Avoid

Common mistakes when using a manual tile cutter include improper alignment and uneven scoring pressure, which can lead to uneven cuts and tile damage.

- Applying too little or too much pressure can result in incomplete scores or broken tiles.

- Not aligning the scoring wheel correctly with the marked line can cause misaligned cuts.

7.1 Incorrect Scoring Technique

Incorrect scoring is a common issue when using a manual tile cutter. Applying uneven pressure or angling the scoring wheel improperly can lead to poor cuts and tile damage.

- The scoring wheel must be aligned precisely with the marked line to ensure straight cuts.

- Using too much pressure can cause the blade to dig into the tile, leading to cracks or breaks.

- Failing to maintain consistent pressure may result in incomplete scores, making snapping difficult.

Proper technique involves steady, controlled movements to achieve clean, precise scores for successful tile cutting.

7.2 Insufficient Pressure or Alignment

Insufficient pressure or improper alignment can lead to uneven cuts and wasted tiles. If the scoring wheel isn’t pressed firmly or the tile isn’t aligned correctly, the score may be incomplete.

- Inconsistent pressure can cause the blade to skip or drag, resulting in uneven cuts.

- Misaligned tiles may lead to angled or offset scores, making snapping difficult or inaccurate.

- Always ensure the tile is snug against the fence and the scoring line is centered under the wheel for clean, precise cuts.

Proper alignment and steady pressure are critical for achieving professional-looking results with a manual tile cutter.

Maintenance and Troubleshooting

Regularly clean the cutter, check for blade wear, and lubricate moving parts to ensure optimal performance. Address issues like misalignment or scoring wheel damage promptly for smooth operation.

8.1 Cleaning and Storing the Tile Cutter

Regular cleaning ensures optimal performance. Use a soft cloth to wipe away dust and debris from the cutter’s surface and blades. For manual cutters, inspect the scoring wheel and rails for dirt buildup. Lightly lubricate moving parts to prevent rust and maintain smooth operation.

Store the tile cutter in a dry, secure location to avoid damage. Keep it away from direct sunlight and moisture. For extended storage, place the cutter in its original packaging or cover it to protect the blade and components from dust and corrosion.

8.2 Replacing Parts (Blades, Wheels, etc.)

Regularly inspect and replace worn or damaged parts, such as blades and scoring wheels, to maintain the cutter’s efficiency. Refer to the manufacturer’s instructions for compatibility and installation steps. Ensure the new blade or wheel is securely fitted to avoid vibration or misalignment during use. Lubricate moving parts after replacement to ensure smooth operation. Proper maintenance extends the lifespan of your tile cutter and ensures precise cuts. Always use genuine or recommended replacement parts for optimal performance.

Advanced Techniques

Mastering advanced techniques with manual tile cutters enhances precision and versatility. Learn to execute mitre cuts, angled cuts, and handle large format tiles with ease and accuracy.

Perfecting these methods ensures professional-looking results, even for complex designs. Proper scoring and snapping techniques are crucial for clean cuts in challenging tile sizes and materials.

9.1 Cutting Large Format Tiles

Cutting large format tiles with a manual tile cutter requires precision and stability. Ensure the tile is securely positioned on the cutter bed, aligning the scoring wheel with the mark. Apply steady, even pressure to score the tile deeply. For especially large tiles, consider making multiple passes to achieve a clean break. Use a rubber mallet to snap the tile along the scored line, maintaining control throughout. Always measure twice and cut once to avoid waste. Proper technique ensures accurate cuts, even for oversized tiles.

For optimal results, use a cutter with a robust design and sufficient capacity for large tiles. Start with smaller cuts to create straight edges before tackling the full length. This method prevents uneven breaks and ensures professional-looking results. Always wear safety goggles and work in a well-lit area to maintain visibility and control during the cutting process;

9.2 Mitre Cuts and Angled Cuts

Mitre cuts and angled cuts require precise alignment and technique when using a manual tile cutter. Set the mitre guide to the desired angle and align the tile accordingly. Score deeply in one steady motion, ensuring the wheel tracks the marked line. For angled cuts, adjust the cutter’s fence to match the angle, maintaining consistent pressure. Snap the tile carefully to avoid chipping. Use a combination of scoring and snapping for intricate mitre joints. Clean, accurate cuts are achieved with proper alignment and controlled pressure, perfect for decorative or complex layouts.

For mitre cuts, ensure the tile is flush against the fence to maintain angle accuracy. Use a pencil to mark the angle clearly before scoring. Apply even pressure during snapping to prevent uneven breaks. Angled cuts benefit from a slower, more deliberate scoring motion. Practice on scrap tiles to refine your technique for consistent results. Always measure twice to ensure the angle aligns with your project requirements. Properly executed mitre and angled cuts enhance the visual appeal of tiled surfaces, making them essential for professional finishes.